Industry analysis of decahydronaphthalene

Decahydronaphthalene (also called decahydronaphthalene, naphthalene), chemical formula C10H18, CAS number 91-17-8, is a bicyclic alicyclic hydrocarbon, a thick ring hydrocarbon, is an important derivative of naphthalene.The appearance is colorless, transparent liquid, with a fragrant smell.Decahydronaphthalene is usually found as a mixture of cis-trans structures.Darkened by light or long-term storage due to oxidation.In the presence of catalyst, it can be oxidized to phthalic anhydride by air.Under certain conditions, sulfonation reaction and nitration reaction can occur.

Decahydronaphthalene is insoluble in water.Soluble in alcohols, ketones, halogenated hydrocarbons, ethers and other organic solvents.Decahydronaphthalene has strong solubility to all kinds of natural resins and synthetic resins, but it is insoluble to all kinds of cellulose and cellulose esters.

Decahydronaphthalene is mainly used as solvent, paint remover and lubricant for grease, resin and rubber in industry.Such as shoe polish, floor wax, car wax and other supplies in the manufacture of decahydronaphthalene can be used as a slow drying solvent, instead of turpentine.Decahydronaphthalene can also be mixed with benzene and ethanol;As fuel for internal combustion engines.Due to the good solubility of decahydronaphthalene to organic solvents, it is often used as an absorber of organic compounds such as aromatic hydrocarbons, low alcohols and acetone.

On the basis of type, the decahydronaphthalene market is segmented into purity < 99% and purity ≥99%.

Analysis of the current situation of decahydronaphthalene industry

Chemical industry: decahydronaphthalene is widely used as a solvent in the chemical industry.It is favored because of its high solubility, low toxicity and non-flammability.The demand for decahydronaphthalene as a solvent is expected to grow due to its application in paints, varnishes, adhesives and lubricants.

Energy sector: Decahydronaphthalene is being explored as a potential fuel additive or as an ingredient in advanced energy storage devices due to its high hydrogen storage capacity.Researchers are investigating its use in hydrogen fuel cells or as a hydrogen storage and release medium.

Hydrocarbon resins: Decahydronaphthalene can be used to produce hydrocarbon resins, which are widely used in adhesives, rubber, coatings and other industries.These resins have excellent viscosity, adhesion and compatibility with other ingredients in the formulation.The development of new grades of hydrocarbon resins using decahydronaphthalene as raw materials is an area of interest.

Technological progress: With the continuous progress of chemical technology, the production process of decahydronaphthalene has also been improved.The purity of decahydronaphthalene can be improved by the new production technology, and the quality of the product can be guaranteed.In addition, the application of some advanced separation and purification technologies also provides technical support for the production of decahydronaphthalene.

Environmental protection requirements: Worldwide environmental protection requirements are getting higher and higher, and restrictions on the use of harmful chemicals are becoming more and more stringent.Compared to other solvents, decahydronaphthalene is less toxic and has less environmental impact.Therefore, decahydronaphthalene has gradually become one of the first choices to replace harmful solvents, and the market demand is also increasing.

Development of international trade: With the deepening of global economic integration, the scale and frequency of international trade continue to expand.Decahydronaphthalene is an important chemical raw material, and its international trade volume is also increasing.In addition, some international cooperation projects have also helped to promote the development of the decalin industry.

Government policy support: In order to encourage the development of local industries, some countries and regions have formulated a series of policies to support the development of decaphthalene industry.For example, export subsidies, tariff reduction and other measures can encourage enterprises to improve the competitiveness of their products and promote the development of the industry.

Development trend of decahydronaphthalene

Alternative harmful solvents: decahydronaphthalene is being investigated as a potential green solvent to replace traditional solvents that are harmful to human health and the environment.Its low toxicity, non-flammability and high solubility make it an attractive alternative in various industries such as paints, coatings and adhesives.

Development of new application areas: With the progress of science and technology, the application field of decahydronaphthalene is constantly expanding.For example, in the field of new energy storage, decahydronaphthalene can be used as a component of high energy density liquid fuels, which is expected to be applied to battery technology, energy storage equipment and so on.In addition, decahydronaphthalene also has potential applications in the synthesis of high performance polymers, pharmaceutical intermediates and other fields.

International market expansion: With the increase of global trade, the demand for decahydronaphthalene in the international market is also increasing.The demand for chemical products in some developing countries and regions is growing rapidly, providing opportunities for the export of decahydronaphthalene.At the same time, the gradually improved logistics system and trade cooperation agreements also provide convenient conditions for the international trade of decahydronaphthalene.

Green production trend: Green production is an important trend in the chemical industry, and it is also the development direction of the decahydronaphthalene industry.Companies will focus on reducing their impact on the environment, improving the efficiency of resource use and actively promoting sustainable development.By adopting cleaner production technology and environmental protection management system, enterprises can improve the added value of products and enhance market competitiveness.

Global decahydronaphthalene scale analysis

Decahydronaphthalene is a toxic, high-boiling colorless organic liquid with a micromenthol odor. It is a typical polycycloparaffin component in diesel oil. It is mainly used as a solvent and paint remover for grease, resin, rubber, etc., and a lubricant. For example, decahydronaphthalene can be used as a solvent to improve the hydrogenation of asphaltene.However, decahydronaphthalene is prone to hydrogen transfer reaction to generate aromatics during thermal cracking under different temperature and pressure conditions, which will reduce the conversion rate of crude oil catalytic cracking and reduce the yield and quality of high value-added products such as gasoline and diesel.In addition, in terms of hydrogen storage materials, decahydronaphthalene has good prospects for development, and is generally used as hydrogen storage materials for fuel cells.

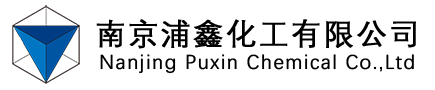

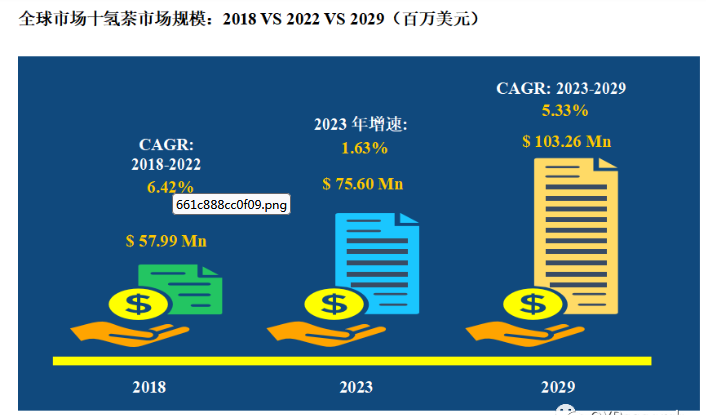

The global decaphthalene market reached $74.39 million in sales in 2022 and is expected to reach $103 million in 2029 with a compound annual growth rate (CAGR) of 5.33% (2023-2029).

At the regional level, the Chinese market has changed rapidly in the past few years, with a market size of 11.43 million US dollars in 2022, accounting for about 15.36% of the global market, and is expected to reach 16.72 million US dollars in 2029, when the global share will reach 16.19%.The Chinese government has given certain policy support to the chemical raw materials and chemical products manufacturing industry, which is conducive to the promotion and application of decahydronaphthalene in the domestic market.Although the domestic decaphthalene market competition is fierce, but some enterprises have better technical level and production experience, these enterprises can improve product quality and reduce production costs to enhance market competitiveness.

In terms of product types and technologies, the market size of decahydronaphthalene with purity < 99% will reach $68.25 million in 2022 and is expected to reach $94.41 million in 2029, with a compound annual growth rate (CAGR) of 5.27%.In 2022, the market size of decahydronaphthalene with purity ≥99% reached 6.14 million US dollars, and the production process of high-purity decahydronaphthalene has undergone stricter quality control, so its quality is more reliable and can meet more stringent quality requirements.Due to the high production cost of high-purity decahydronaphthalene, its price is also relatively high, which brings higher added value to the producer.

From the perspective of product market application, the solvent-based decahydronaphthalene market size reached 67.22 million US dollars in 2022 and is expected to reach 93.28 million US dollars in 2029, with a compound annual growth rate (CAGR) of 5.32%.

At present, the major manufacturers in the world include Evonik Industries, BASF, Monument Chemicals, Nanjing Puxin Chemical etc., and the share of the top3 manufacturers in 2022 has reached 86.67%. It is expected that the industry competition will be more intense in the next few years, especially in the Chinese market.The prospects for decalin are good, driven by increasing demand from the chemical industry, growing demand for sustainable solvents, advancements in fuel cell technology, pharmaceutical and fine chemical applications, development of functionalized derivatives, exploration of niche industries, and opportunities for collaboration.Companies and researchers can leverage these prospects to drive growth and innovation in the decalin industry.

With the development of science and technology, the production process and technology of decahydronaphthalene have been continuously improved, and the production cost has been continuously reduced.This reduces the market price of decahydronaphthalene and increases its competitiveness, while also providing conditions for large-scale commercial production.With the enhancement of environmental awareness and the intensification of the energy crisis, green environmental protection, energy saving and emission reduction have become the focus of attention, which also brings new opportunities for the decahydronaphthalene market.However, during the production and use of decahydronaphthalene, some harmful substances and wastes may be generated.These pollutants may cause harm to the environment and human health, and corresponding environmental protection measures should be taken to deal with them.Closed operation to prevent steam leakage into the workplace air.The workplace should provide good ventilation to keep concentrations in the air below occupational exposure limits.